Owner: Josh Go Hard Neal

Year: 2012

Model: Maxima

Color: Charcoal

Transmission: 6-Speed Manual

Trim: SV

![]()

Owner: Josh Go Hard Neal

Year: 2012

Model: Maxima

Color: Charcoal

Transmission: 6-Speed Manual

Trim: SV

![]()

Member Credit: Child_uv_KoRn Bad

Miles are unknown on the motor. I’m gonna say….very low miles. It blew oil vapor out of the crank case for a couple thousand miles, so it’s safe to say she was basically brand new.

I cleaned and window welded the old mounts. I forgot to take pics, but you know how cracked up and falling apart they are at this age. I used the 3M tube and shot it into any cracks then filled up the vacant spots and added a layer on the outsides. Obviously, burning/cutting them up and filling is the best way. I’m cheap and lazy.

I opted for a 4″ grinder with a cutting wheel to do the PS modding (Darren used hack saw, iirc). You can lop off most the bottom ear, then cut slits in both of them and break out the pieces with a chisel. Test fit the pump and you’ll see where it hits the block. Grind off a little more there and you can really make it easy to get the belt off. Grinder makes a lot of mess. Make sure the motor is sealed up good enough (I washed it with a hose afterwards).

UD PS pulley is in the mail. So, ignore this stupid, ugly thing.

DOUBLE CORRECTION Pulleys looked aligned originally, but it’s clearly misaligned. I thought alternator was off compared to the AC/crank pulley, but i was wrong. The compressor is like 4mm off from the crank/alternator on this particular engine (no one elses is like this apparently). It makes the belt squeal when it heats up b/c it’s rubbing on the alty pulley AND rubbing sideways accross tensioner pulley (tried to align the atly between crank and compressor, didn’t work). I resorted to using tiny washers (in retrospect, making a half moon would work) to shim the tensioner pulley to the appropriate angle towards the alty pulley and aligned it with the compressor. I have no idea why my engine is different, but this worked. The belt runs “straight” across the tensioner pulley. I believe Daren just had to shim the alty with a couple washers.

I didn’t have the luxury of the new bracket, so I took a junk piece of metal and made my own connecting to the old bracket. Here’s what it looks like before molesting scrap metal.

Being the lazy *** that I am, I decided to leave the new coolant pipes up top (connector mounts/brackets be damned). The hose already on them works great to bypass the TB coolant asshatery from Nissan.

For the lower pipes, I kept the originals – Por 15’d them and kept the oil cooler thingy, which works out great for the MASSIVE pl-14619 filter. I recommend replacing the oil cooler hoses. Also, replace the oil cooler O ring (it will leak later).

I went kinda crazy on the tensioner. I stacked four 3/4″ lock washers and trimmed the top of the tensioner nut off to gain more clearance. I did it before fully testing LOL. I don’t think it was necessary…. It looks like I needed more washers than Darren, since I have an UDP. I also ground down the back of the pulley bolt some b/c I couldn’t freely slide it up and down.

The new nylon hose is smaller, so I used two different adapters and screwed them together (with permanent thread lock lol). I couldn’t find a barbed coupler with different diameters at the ****ty hardware stores.

I am using a 7th gen IM and TB on this engine. I want to retain as much power as possible. No EVT will be the only difference. Three pullies being lightweight/UDP should easily offset the loss of EVT.

Is it me or are arp bolts kinda sexy?

retarding cam wheels didn’t work, lovely

edit: Fixed after Darren sent me a pic.

I underestimated how much larger this pulley would be since it’s underdriving LOL. This thing must be 6″ .The sentras stock pulley causes cavitation at high rpm, so it’s even more oversized. It’s not that big of a deal, I just cut off that little arm on the bracket.

What I did forget is that they don’t use a two belt system, so it has two more ribs. 32″ belt works perfect and alignment is with the belt in the middle.

So, yeah, SR20 pulley is definitely a better idea for the non-rigging crew

You’ll notice a piece missing haha. The pulley is 5.5″.

USE THIS OPPORTUNITY TO REPLACE POWER STEERING HOSE AS IT’S JUST ONE LESS THING TO REPLACE LATER

Mmmm, new friction plate

PCV? Nonsense crap!

Extended IVT wires

quick and dirty recap (can I do anything right lol) of what is not in my thread:

These are needed from old engine:

Before loom

After loom

I couldn’t find it actually posted anywhere where it loaded, but google had it

Alright folks, here ya go! Nice NiCopp clutch line!

Late pic for funsies. I forgot the balancer and chains LOL. I strapped the motor in and out and pulled the tranny up with them

![]()

Credit: Gerson Flores

Owners of the 2009-2014 7th generation Maxima with a 6-speed manual transmission can now enjoy restored OEM-style cruise control functionality after the swap, thanks to a new tuning update. This retune also brings rolling anti-lag, launch control, and flatfoot shifting. A full retune is required to implement these features.

Contact: https://www.instagram.com/gtunedperformance/

![]()

Photo Credit: Rene Saran, Jose Vargas, Rabbit Hole Motorsports

Push-In -8AN fittings to accommodate the 5/8″ PCV tube found on VQ engines valve covers to clean up your Oil Catch Can setup. These are AN fittings designed to be pushed in your engine valve cover plastic tube outlet, they do not replace the threaded PCV Valve. Made with precision machined 6061-T6 Aluminium, hard-anodized finish and laser-etched RHM logo.

You can order on their website or contact on Facebook.

![]()

Credit: Ballistic Autowerks

I get asked about this frequently. These vehicles are extremely sensitive when it comes to adding accessories to the battery, even with a factory alternator that ranges from 130 to 160 amps depending on the brand. Upgrading the “Big 3” components of the electrical system is crucial for accommodating additional add-ons such as air suspension, stereo systems, underglow, interior lights, and more.

We offer pre-made Big 3 kits specifically designed for these cars, including the dealer for JS Alternators. Today, we completed one of these installations (with unlimited color options available) using the customer’s existing setup and enhancing it with a Big 3 upgrade to prevent power drops. This upgrade is beneficial not only for aftermarket setups but also for maintaining the health of the battery and alternator in factory configurations.

![]()

Credit: Waleed Ali

I took my fourth-generation vehicle to Casey, my fabricator. He assured me that he could provide an improved solution at a lower cost compared to buying an OEM radiator support and paying for labor. Check out the quality of Casey’s work—it’s impressive!

![]()

Member Credit: Aaron92SE

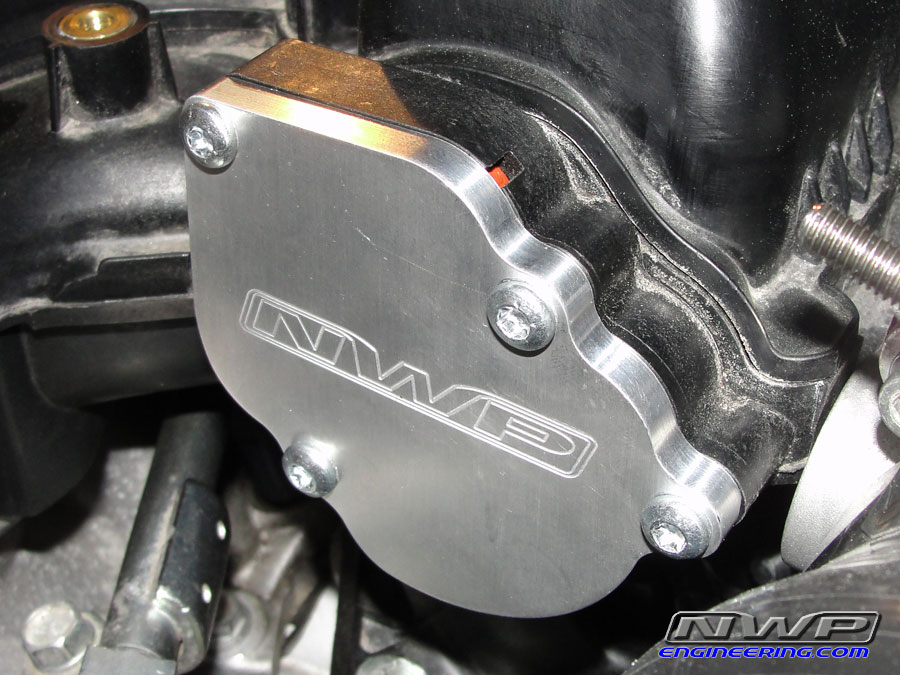

Ever since the 2009 Maxima came out, I knew that an NWP Engineering VIAS Block Plate Kit could possibly be a great modification to offer to the community. And for the past year or so, I have been working on this project for the 7th gen 2009+ Maxima. I realize that a block off plate kit is currently being sold by someone else. But, I do not feel it’s necessary to abort a project simply because a different kit came out before we had a chance to finish our testing.

Here are some pictures of the NWP Engineering prototypes:

Several hours have been spent on the dyno testing these prototypes. The stock 7th gen Maxima only comes with a CVT (Continuously Variable Transmission). This means that the gear ratios are always changing during the dyno pull. Since this is the case, you are unable to accurately use the dyno charts to determine HP gains and losses in various parts of the powerband. Simply put, running a CVT on a dyno can possibly provide some ballpark numbers to look at, but they will not be accurate in determining low end, midrange, and top end HP results and comparing before and after dyno runs. The only way to properly dyno test a vehicle with a CVT transmission is to lock it into a 1:1 gear ratio and currently, this has never been done on a 7th gen Maxima

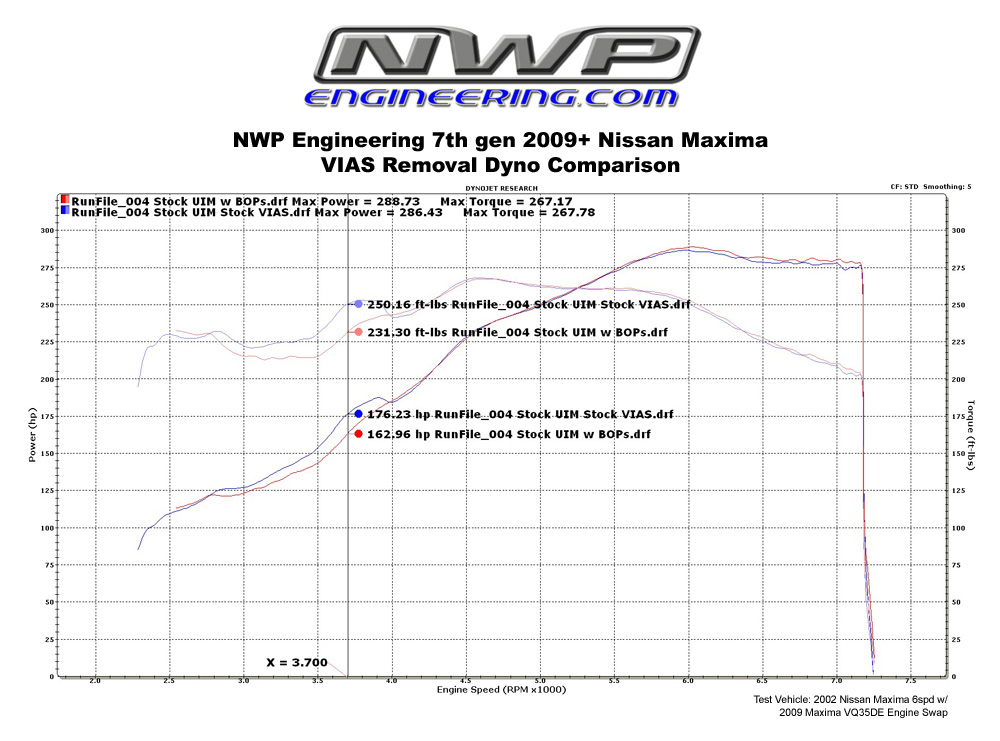

Here is a before and after dyno comparison of a stock intake manifold with stock operating VIAS actuators versus the VIAS actuators being removed and block plates installed:

As you can see, there is a huge 19 ft-lbs of torque loss in low end power and roughly only a 2HP increase on top end. But, this is only comparing two dyno runs. If you know how NWP Engineering does dyno testing, you know that we are way more accurate than this! We always like to take an average of all the dyno runs.

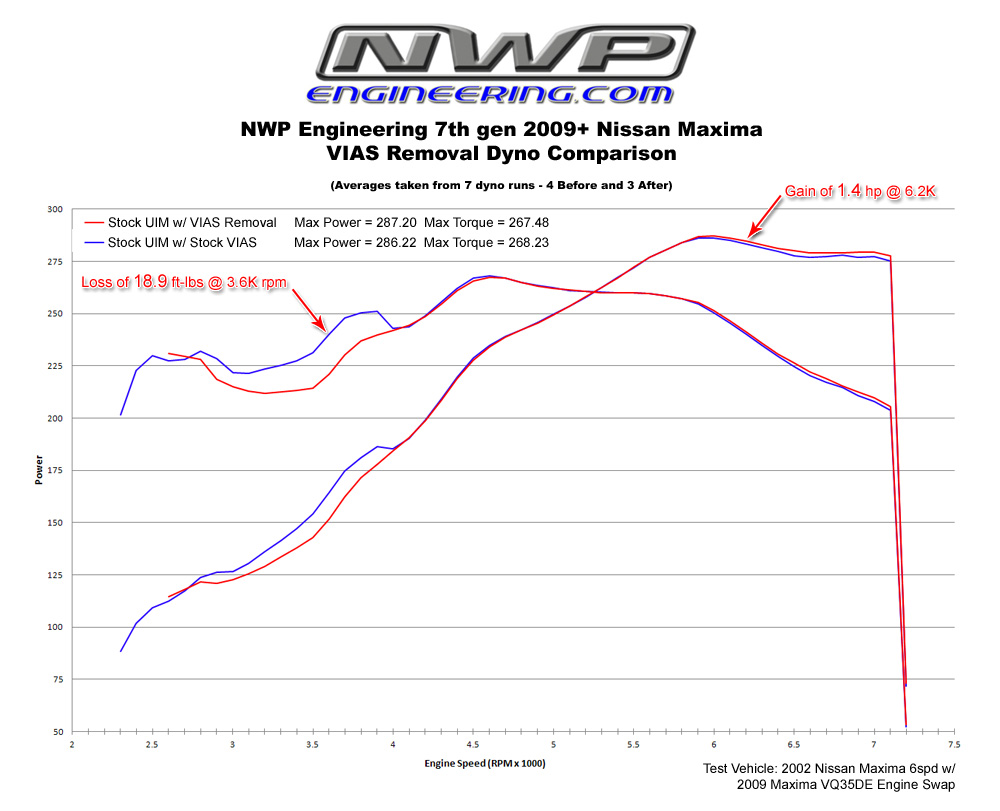

We did 4 dyno runs before and 3 dyno runs after the NWP Block Plates were installed. Then, we exported the runfile data to an Excel spreadsheet so that the numbers can be analyzed more thoroughly. Horsepower and torque data was taken at every 100rpm and used for this comparison. At every 100rpm increment for every dyno run, an average was calculated and then plotted on the dyno chart shown below.

Since the 2009 engine was running so consistent, our average dyno comparison chart looks almost identical to the two dyno runs shown above. But, these average results are even more accurate than simply comparing two dyno runs with one another.

As you can see from this dyno chart, that by eliminating the VIAS actuators, there is a low end torque loss of 18.9 ft-lbs at 3600rpm with an average loss of 14.6 ft-lbs between 3200-3900 rpm. And there is a gain of 1.4HP at 6200rpm with an average gain of 1.3HP between 6000-6400 rpm where the 09 Maxima CVT holds the revs at during a wide open throttle run.

In order for your Maxima to accelerate at the same rate or faster from 0-60mph or in the 1/4 mile, you will need a much greater top end HP gain to compensate for the big low end power loss even with the efficiency of a CVT. So in other words, your car will accelerate slower from 0-60mph and in the 1/4 mile with the VIAS actuators removed.

I am really surprised with the efficiency of the stock 09 Maxima Upper Intake Manifold (UIM) with the stock variable induction air system (VIAS).

Unfortunately, the results are not what we had hoped for. I knew there would be a low end power loss, but I didn’t know it would be this large of a loss. And I really thought there would be a noticeable top end HP gain to make it worth it overall like the 02-08 Maxima VIAS removal does. But, what seems to work for the 02-08 VQ35DE Maxima does not necessarily work on the 2009 and newer VQ35DE Maxima.

Due to what was proven in our testing, I do not see a need to produce the VIAS Block Plate Kit for the 2009 and newer Maxima. But, I feel compelled to share this information to the Nissan community to let you know what kind of projects NWP Engineering has been working on lately.

As you can see, we thoroughly test all our products before they are released. I won’t release a product unless it has been proven to benefit your car’s performance. This is not the first time we’ve tested an NWP prototype and had to abort it due to low performance gains.

![]()

Credit: Kristan Clarke

I’m currently using a 100 shot wet kit that produces around 400 WHP. The nitrous is injected near the throttle body in the intake;.

![]()